IMI Europe Inkjet Development Conference

Wednesday 18 - Thursday 19 March 2026

Hyperion Hotel, Hamburg, Germany

Conference Programme

The IMI Europe Inkjet Development Conference is aimed at inkjet development technologists looking to find out about the latest products, technology and techniques, while also giving the opportunity to exchange ideas with their peers.

This is a two-day technical conference devoted to digital printing technology development, covering materials, engineering and solutions. The event covers applications including 3D printing/additive manufacturing, packaging, textiles, graphics, industrial and functional printing. The conference gives access to key suppliers, technology, information and inspiration from the inkjet industry – everything that you need to develop inkjet technology.

Topics for the event include functional and 3D printing, colorants, material dispersion, resins & polymers, photoinitiators, additives & other materials, analytical equipment & techniques, processing & manufacturing equipment, drop & surface behaviour and application case studies.

TECHNICAL ADVISORY BOARD

The conference is guided by a Technical Advisory Board consisting of key industry figures, chaired by Dr Tim Phillips of IMI Europe.

Dr Mark Bale, Director, DoDxAct

Dr Vedran Durasevic, Technical Manager Water Based Inkjet Inks, Heidelberg

Dr Tri Tuladhar, Principal Consultant, Trijet Limited

Dr Tim Phillips, Managing Director, IMI Europe & Catenary Solutions

Dr Andrew Mellor, Applications & Markets Manager, KRÜSS

Additional Benefits

Networking

Meet with suppliers, industry experts and developers from other companies at our networking breaks, lunches and evening drinks reception. Excellent refreshments will help you enjoy this key part of the conference.

Sponsor Exhibits & Forum

Event sponsors will have their products and technology on display in the breakout area. In addition the Sponsors' Forum enables you to hear short presentations from sponsors with their latest news. If you are interested in becoming an event sponsor, please visit our sponsorship page.

Conference Programme

Conference Programme

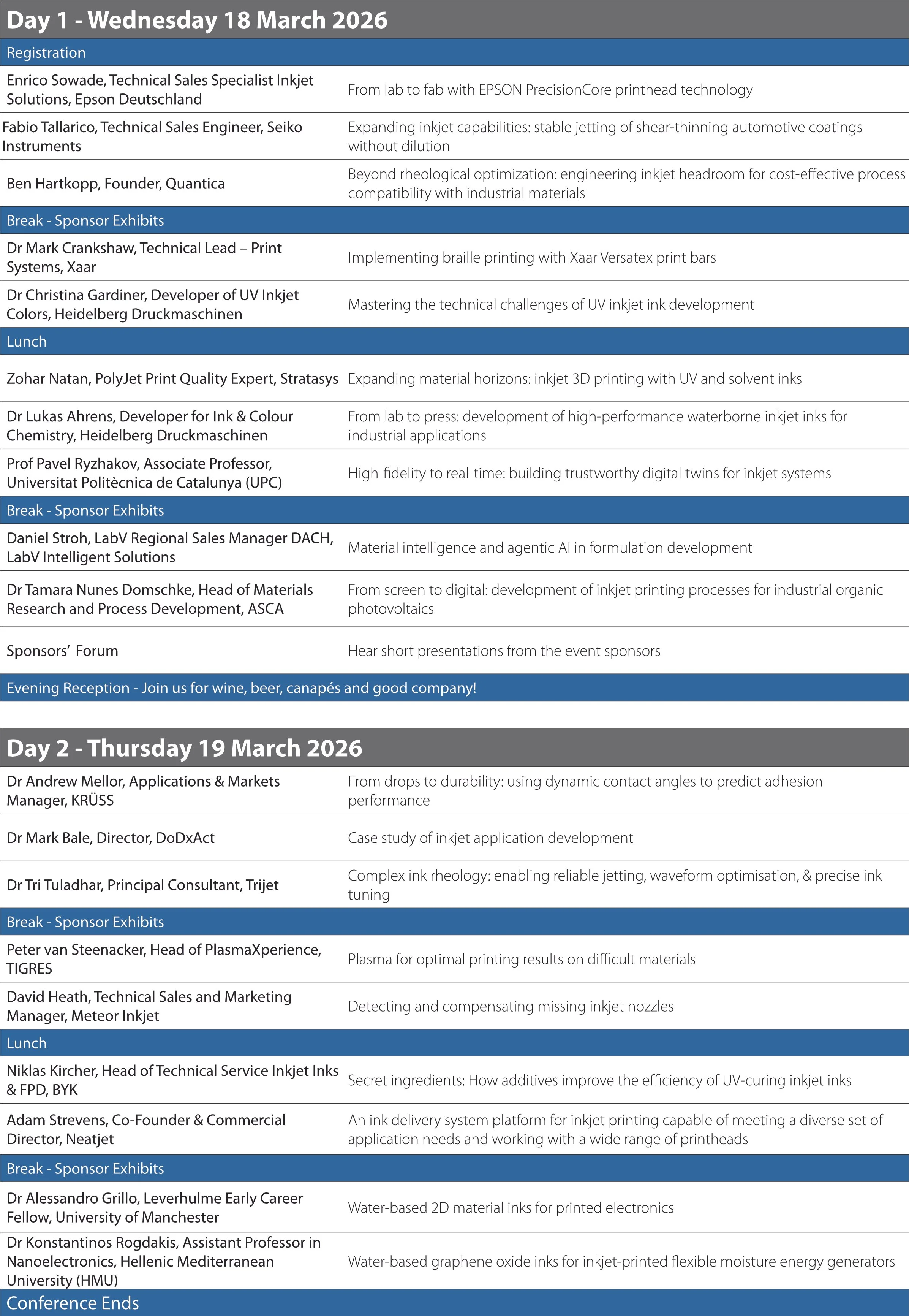

Wednesday 18 March 2026

From lab to fab with Epson PrecisionCore printhead technology

Enrico Sowade, Technical Sales Specialist Inkjet Solutions, Epson Deutschland

Epson PrecisionCore printheads use a technology platform comprising of modular print chips, that can be arranged into various printhead configurations. This platform enables a single technology to scale easily, for example from desktop printers to large industrial single-pass systems or from laboratory use in R&D to high-volume production printing in applications such as electronics fabrication.

This technology offers high flexibility of ink compatibility and allows excellent, application-driven jetting performance in a cost-effective solution to meet demanding customer requirements.

The presentation will provide an overview of Epson’s printhead technology, including new additions to our range, providing products to suit every stage of development from “Lab to Fab”.

Expanding inkjet capabilities: stable jetting of shear-thinning automotive coatings without dilution

Fabio Tallarico, Technical Sales Engineer, Seiko Instruments

Conventional inkjet systems are optimized for low-viscosity Newtonian inks, limiting their use in industrial coatings. Automotive paints typically exhibit high viscosity and pseudoplastic (shear-thinning) behavior, placing them beyond the practical range of standard drop-on-demand technology. Building on recent progress in high-viscosity jetting, this study employs a modified RC1536 piezoelectric printhead to achieve stable, high-frequency ejection of undiluted automotive paint. The influence of shear-dependent viscosity on droplet formation and jet stability was systematically analyzed to clarify key process–material interactions. The results demonstrate that tailored printhead design enables reliable jetting of complex rheological fluids, significantly broadening the application range of inkjet technology for digital coating and advanced manufacturing processes.

Beyond rheological optimization: engineering inkjet headroom for cost-effective process compatibility with industrial materials

Ben Hartkopp, Founder, Quantica

The adoption of digital deposition is frequently stalled by the requirement to reformulate proven industrial materials to meet strict inkjet rheology windows. This constraint often compromises functional performance and renders production cost-prohibitive. This presentation introduces the Quantica NovoJet™ architecture, engineered specifically with the headroom necessary for real-world manufacturing. We explore how its high-force volumetric displacement and robust single-pulse actuation accommodate typical rheological batch variations and larger particle sizes without complex waveform retuning. By enabling the deposition of conductive pastes and adhesives that are optimized for material properties and production cost rather than rheology, we demonstrate how this technology integrates realistically with existing manufacturing lines, making digital production robust, scalable, and cost-effective.

Implementing braille printing with Xaar Versatex print bars

Dr Mark Crankshaw, Technical Lead – Print Systems, Xaar

“We need to make every single thing accessible to every single person with a disability.” — Stevie Wonder

Traditionally, braille is embossed onto cartons using embossing tooling, but advances in digital printing—like Xaar print bars with high-build capabilities—offer new ways to add braille without physical embossing. This presentation describes braille printing and its standards and shares research insights from using Xaar Versatex print bars to print braille dots that meet industry requirements. It will discuss braille basics and regulations, then delve into practical findings on optimising dot height, diameter, substrates, and process settings for readable, compliant braille.

Mastering the technical challenges of UV inkjet ink development

Dr Christina Gardiner, Head of R&D UV Inkjet Inks, Heidelberg Druckmaschinen

UV inkjet inks are driving innovation in digital printing, but their development is anything but simple. How do we ensure flawless jetting, rapid curing, and strong adhesion on a wide range of substrates—from flexible films to rigid plastics—without compromising color brilliance or durability? Behind every print lies a complex interplay of chemistry, physics, and engineering. This talk will uncover the critical formulation challenges, from controlling viscosity and surface tension to preventing nozzle clogging and sedimentation. Join us to explore the science behind high- performance UV inkjet inks and discover strategies that push the boundaries of what’s possible in digital printing.

Expanding material horizons: inkjet 3D printing with UV and solvent inks

Zohar Natan, PolyJet Print Quality Expert, Stratasys

Inkjet 3D printing enables the fabrication of complex structures through precise, layer-by-layer deposition of functional inks. These inks are typically UV-curable or solvent-based, each presenting distinct processing requirements and limitations. UV-curable inks solidify under ultraviolet light, offering excellent geometric control and high resolution, but require careful formulation to balance viscosity, curing rate, and mechanical properties. Solvent-based inks rely on evaporation to form solid layers and allow deposition of non-photocurable materials such as metals or ceramics, yet introduce challenges in drying dynamics, surface interaction, and layer uniformity. This talk will examine the printing processes, inherent disadvantages, and complexities of both approaches in the context of multi-material 3D printing

From lab to press: development of high-performance waterborne inkjet inks for industrial applications

Dr Lukas Ahrens, Developer for Ink & Colour Chemistry, Heidelberger Druckmaschinen

Industrial inkjet printing pushes water-based inks to their limits, demanding exceptional jetting reliability, fast drying, highest print quality and durability across diverse substrates. Our approach integrates formulation science with mechanical insights from custom-built test rigs, enabling controlled studies of ink–printhead–press interactions. This deep understanding allows us to engineer inks that maintain stability under high shear, resist nozzle clogging, and deliver superior print quality at elevated speeds. The talk will share lessons learned from iterative lab-to-press development, emphasizing how collaborative engineering and chemistry drive innovation in sustainable inkjet solutions.

High-fidelity to real-time: building trustworthy digital twins for inkjet systems

Prof Pavel Ryzhakov, Associate Professor, Universitat Politècnica de Catalunya (UPC)

Developing trustworthy digital twins for inkjet systems requires balancing the accuracy of high-fidelity models with the efficiency of real-time surrogates. Inkjet droplet formation involves tightly coupled multiphase flow phenomena, complex interface dynamics, and strong sensitivity to operating conditions, making predictive modeling and control highly challenging. To address these issues, we developed advanced computational fluid dynamics (CFD) methods that combine an Enriched Finite Element Method with a Conservative Level-Set formulation. The resulting architecture manifests the synergy between experiments, high-fidelity simulation, and machine learning, providing a foundation for closed-loop digital twins capable of stability assessment, process optimization, and adaptive operation. This approach advances the deployment of reliable real-time control systems for industrial inkjet applications in printing, coatings, biomedicine, and microelectronics.

Material intelligence and agentic AI in formulation development

Daniel Stroh, LabV Regional Sales Manager DACH, LabV Intelligent Solutions

Formulation development in inkjet and coatings R&D is often slowed by fragmented data, isolated experiments and the loss of contextual knowledge across projects and time. Formulation data, test results and specifications are typically distributed across databases, documents and individual experience, limiting systematic reuse and informed decision-making. This presentation introduces a Material Intelligence approach that establishes structured data and reproducible workflows as the foundation for AI. On this basis, an AI-supported Co-Engineer is implemented using an agentic, multi-agent architecture. Specialised search, analysis and prediction agents operate directly on formulation data and technical documents, coordinated by a supervisor agent to provide context-aware support rather than autonomous decisions. The introduction of this Material Intelligence framework can lead to a measurable reduction in formulation iterations per project of approximately 30 %, a decrease in documentation effort per experiment and per project of around 50 %, and a reduction in time spent on data retrieval of about 66 %. As a result, development workflows become more efficient and transparent, enabling better-informed formulation decisions with fewer unnecessary iterations.

From screen to digital: development of inkjet printing processes for industrial organic photovoltaics

Dr Tamara Nunes Domschke, Head of Materials Research and Process Development, ASCA

ASCA GmbH & Co. KG is a global leader in organic photovoltaics (OPV), leveraging the unique features of this technology to deliver creative and highly customized solar solutions. In the context of industrial OPV manufacturing, the transition from screen printing to digital inkjet printing offers major advantages in design flexibility, scalability, and production yield. Moreover, inkjet printing enables precise material deposition and complex pattern customization, fully unlocking the potential of ASCA’s free-form technology. Following a successful proof-of-concept phase, this presentation outlines the optimization of process parameters and curing conditions, and discusses the key challenges encountered during the initial development phase of inkjet printing for ASCA’s OPV modules, where aesthetics, precision, and functionality are critical.

Hear short presentations from the event sponsors.

Join us for wine, beer, canapés and good company!

thursday 19 March 2026

From drops to durability: using dynamic contact angles to predict adhesion performance

Dr Andrew Mellor, Applications & Markets Manager, KRÜSS

The contact angle measurement, often regarded as a simple technique, has long been a cornerstone of the coatings specialist’s toolkit. It is used to guide formulation decisions and to evaluate performance related to wettability, (re)coatability, defect control, adhesion, and more. Although static contact angles are widely used, dynamic contact angle measurements tend to receive far less attention, mainly because they are significantly more complex and time-consuming.

In this project, we present a collection of studies that demonstrate a strong correlation between dynamic contact angle measurements, specifically recently receded contact angle data, and substrate–coating adhesion performance as assessed using ISO 2409 (cross-cut adhesion and tape test). This relationship was validated across a broad selection of substrates, including metals, polymers, plasma-treated polymers, and base-coated materials paired with different coating systems. A central feature of this work is the adoption of a novel measurement approach known as the stood up-drop method. This technique enables rapid and reliable measurement of recently receded contact angles and reduces the typical measurement time to only seconds per sample, even with repeats included.

Case study of inkjet application development

Dr Mark Bale, Director, DoDxAct

All successful inkjet applications are enabled by the correct chemistry selection for the end-use performance but the path to successful manufacturing of products involves a holistic view of all the things that can influence jetting and printing reliability in a final printer. The best result is not always arising from the perfect theoretical solution, but a compromise based on measured attributes such as droplet formation misting, nozzle wetting effects & nozzle open time. Using practical examples, we describe how it is possible to mitigate some of these risk factors by a combination of dropwatcher and print tests and thus provide the necessary feedback loop into reformation during the development process.

Complex ink rheology: enabling reliable jetting, waveform optimisation, & precise ink tuning

Dr Tri Tuladhar, Principal Consultant, Trijet

Reliable inkjet performance requires an understanding of ink behaviour beyond steady-shear viscosity, particularly under the high deformation rates encountered during jetting. This work demonstrates how frequency-dependent viscoelastic properties can be directly correlated with printhead dynamics and waveform parameters, including rise time, dwell, and pressure wave propagation. Using the TriPAV printhead mode to replicate realistic jetting conditions, rheological signatures are linked to droplet stability, satellite suppression, and waveform optimisation. The results highlight how integrated rheological and printhead analysis enables faster formulation development, predictive ink fine-tuning, and improved jetting reliability across functional and industrial inkjet applications.

Plasma for optimal printing results on difficult materials

Peter van Steenacker, Sales, Head of PlasmaXperience, TIGRES

Printing on many plastics, as well as glass and metal, can repeatedly lead to problems with adhesion and wetting. Polyolefins in particular, such as polyethylene (PE) and polypropylene (PP), but also many other plastics, are difficult to print on due to poor adhesion properties and wettability. When it comes to poor adhesion properties and wettability, the problem can be divided into three sub-areas, which may overlap in their effects.

1. Poor adhesion properties of the base material

2. Poor wettability

3. Contamination of the surface

Plasma pretreatment as a tool for improving wettability and adhesion as well as for cleaning the surface.

Detecting and compensating missing inkjet nozzles

David Heath,Technical Sales and Marketing Manager, Meteor Inkjet

In industrial inkjet, nozzle failure is more than a technical glitch. It is a primary driver of material wastage and costly system downtime. Driven by complex factors like wetting, air ingestion, and blockages, missing nozzles can compromise print quality across all applications. This session explores how nozzle failure occurs and evaluates the evolving landscape of new technologies that are still arising to address this issue. With reference to Meteor’s latest Nozzle Health Technology (electrical sensing) and MetVision (camera-based sensing) and how these feed into Meteor’s NozzleFix algorithms that compensate for failures in real time to ensure continuity of reliable output.

Secret ingredients: How additives improve the efficiency of UV-curing inkjet inks

Niklas Kircher, Head of Technical Service Inkjet Inks & FPD, BYK

This presentation provides an overview of how specialized additives enhance the performance, efficiency, and quality of UV‑curing inkjet inks. It highlights the crucial role of wetting and dispersing additives in stabilizing CMYK and TiO₂pigments for inkjet printing, ensuring long‑term storage stability, preventing settling, and enhancing filterability. Key focus areas include improving jettability through tailored surface additives, controlling foam behavior, and optimizing substrate wetting under high‑speed jetting conditions. The portfolio also covers solutions for achieving consistent droplet formation, superior leveling, and robust surface properties—enabling high‑quality, energy‑efficient, and versatile UV inkjet formulations.

An ink delivery system platform for inkjet printing capable of meeting a diverse set of application needs and working with a wide range of printheads

Adam Strevens, Co-Founder & Commercial Director, Neatjet

This talk will first provide some background of ink delivery system (IDS) design requirements. A quantitative explanation of how Neatjet systems meet these requirements will be given. The talk will cover both lab solutions and full production solutions. Then examples of configurations used for conventional inkjet inks whether they be aqueous, UV-curable, oil-based or solvent will be given. Finally, some examples of IDS implementations for different print productivity levels will be presented. The aim is to show how different components can be easily added or swapped out, and settings altered to cater for several different use cases.

Water-based 2D material inks for printed electronics

Dr Alessandro Grillo, Leverhulme Early Career Fellow, University of Manchester

Printed electronics based on solution-processed two-dimensional (2D) materials offer a sustainable and scalable route to device fabrication, combining digital patterning, low-temperature processing, and minimal material waste. While transistors have dominated the field, diodes remain essential yet underexplored components for signal rectification, detection, and circuit integration. In this talk, I will present recent advances in the development of 2D-material-based diodes realised entirely through inkjet printing. We first demonstrate the integration of printed graphene and MoS2 inks with silicon technology, achieving both Schottky and metal–insulator–semiconductor (MIS) architectures that are fully compatible with back-end-of-line (BEOL) processing. These devices exhibit excellent rectification, low leakage currents, and tuneable barrier properties, representing a milestone in hybrid additive–CMOS integration. Building on this approach, we extend printed 2D electronics to flexible and sustainable substrates, realising the first fully printed diodes and functional circuits on paper made entirely from 2D inks. The resulting devices display high rectification, stable operation, and mechanical flexibility, enabling the fabrication of printed rectifiers, filters, and AC–DC converters. Altogether, this work establishes a coherent pathway for integrating solution-processed 2D materials from silicon technology to fully printed, sustainable platforms, paving the way toward scalable, low-power, and environmentally responsible electronics.

Water-based graphene oxide inks for inkjet-printed flexible moisture energy generators

Dr Konstantinos Rogdakis, Assistant Professor in Nanoelectronics, Hellenic Mediterranean University (HMU)

With the need for clean sustainable energy and low-waste practices rising, battery-free technologies that run on renewable ambient energy sources are an attractive solution to these environmental concerns. Herein, Graphene oxide (GO) and GO-PEDOT: PSS water-based inks were formulated from inexpensive precursor materials following user-friendly, up-scalable methods. GO-based moisture-active films were deposited on flexible lightweight substrates using inkjet printing to fabricate Moisture Energy Generators (MEG), devices that convert ambient moisture energy variation into a voltage output. The role of material composition and printing parameters on the performance of the fabricated MEGs was evaluated. Devices with an average voltage output higher than 200mV are presented. We support that this study may provide fertile ground for the development of low-cost energy harvesters for self-powered portable and wearable technologies, minimising the need for batteries and reducing electronic waste.