Introduction

There are many processes that can be used to deposit thin metal oxide films and each technique offers advantages and disadvantages. For example, in vapour deposition the high purity precursors used, that can be evaporated uniformly without decomposition and transported to the substrate intact and then deposited into a high quality film directly, mean relatively high costs for gas delivery control lines and highly specialised systems. Inkjet printing offers significant cost advantages and allows direct writing of patterns to reduce process steps but employs additives and solvents to deliver the material that the thin film is to be formed from. These extra components require removal leading to lower quality initial dried films that need further treatments to improve properties adding to complexity. The use of high temperatures to achieve thin film properties is perfectly suited to rigid glass/metal/ceramic substrates however is not compatible with plastic, flexible substrates.

Numerous printing formulations exist based on two approaches:

- a) nanoparticles in an inert binder/stabiliser system

- b) precursor in solvent/stabiliser system.

Approach a) can deliver very high quality nanoparticles that have been treated beforehand to the substrate but after deposition a thermal treatment is required to remove the additives/binders and join the nanoparticles together to form a coherent, continuous film. Approach b) delivers active molecules to the substrate that react/decompose to form the target film but again a thermal element is involved to acquire high quality continuous films.

The combination of the two approaches detailed has been investigated to select the advantages from each to create an enhanced process by using an active matrix to improve the nanoparticle joining at reduced temperatures more compatible with plastic substrates. In effect the inorganic nanoparticles are “glued” together by the inorganic matrix.

The highly crystalline nanoparticles act as seeds to template the solution phase growth of metal oxide coating which encompasses the nanoparticles to form an embedded film. Where the nanocrystal and matrix film yield the same metal oxide material a continuous homogeneous film is formed. Due to the reactive nature of the active matrix the thermal budget to achieve the connectivity of nanoparticles is reduced and by carefully increasing the nanoparticle mass included the properties of the film tend towards those of the high quality nanoparticles.

Active matrix development

The active matrix on its own should be capable of producing high quality metal oxide films, however, its main purpose in this process is as a nanoparticle “joiner” to facilitate connectivity of ultra high quality nanoparticles. To deposit high quality films the active matrix must contain highly reactive precursors but also be printable hence a balance of atmospheric sensitivity vs. film formation must be achieved. Initial work involving simple metal alkoxide solutions in hydrocarbon yielded acceptable films in drop tests but the solutions were not printable due to high reactivity to form particles that either blocked the inkjet printing head or led to uneven, low quality films on the substrate or both.

To reduce the sensitivity of these solutions a series of additives and stabilisers were explored with functional alcohols and glymes identified as the best performing systems. The resulting formulation was shown to resist change on air exposure for well over 24hrs (Fleming B, Rushworth S, Journal of Sol-Gel Science and Technology, 82(1) 308-314, 2017).

Printing results

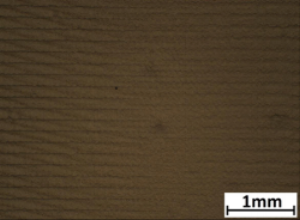

As an example, printing of TiO2 from an active matrix with and without nanoparticles is illustrated below and a coherent structure has been achieved even after drying at less than 100C. Further thermal treatment or laser annealing can be employed to improve the film properties further for optical or electronic applications whereas the films on their own are in theory useful for catalytic or antimicrobial applications (tests are underway and results will be disseminated when available).

Inkjet printed TiO2 overlapping tracks from active matrix ink:

left) without nanoparticles and right) with nanoparticles

Summary

The range of potential applications for the use of nanoparticle inks with active matrix materials is huge because the composition of the deposited films and patterns can be tailored to meet requirements. The use of heterogeneous systems to embed different functionality nanoparticles in a host matrix could easily lead to multifunction systems with surfaces that could perform different actions simultaneously i.e. mixed gas sensors, conducting antibacterial coatings, colour filters etc.

by Casey Dixon and Simon Rushworth, Epivalence.

Further details of this exciting work will be presented by Dr Casey Dixon at the IMI Europe Inkjet Development Conference, 17-18 April 2018 in Frankfurt, Germany

This work has been supported by the EU funded project “INFINITY” - European Union’s Horizon 2020 research and innovation programme grant agreement No 641927 and by an EPSRC Case Award for Josh Turner’s PhD studies.