In a wide range of textile applications, fabrics are selected not only for their aesthetic appearance but also for their functional properties. Different levels of toughness, thickness and flexibility can be achieved by constructing a fabric in a particular way (woven, knitted or non-woven). However, for applications where specific functional properties are required from the fabric, the deposition of additional coatings may be required. Some of the most common coatings give fabric properties such as: hydrophobic, hydrophilic, anti-abrasion, anti-bacterial, flame retardant and UV blocking. While the deposition of functional coatings has been around for decades using traditional methods, inkjet has only emerged as an alternative method in the last few years. The main area of development has been achieving the right formulation to allow non-ideal fluids to be jetted reliably, precisely and in metered quantities.

Inkjet deposition

Using inkjet technology, fluid deposition is precise in terms of droplet location, which can be particularly beneficial in applications which require multiple coatings on a single substrate (outdoor work wear is a prominent example). Inkjet functional finishings also incur the benefits of fast turnaround time, maximum customisation, reduced wastage and improved energy savings. Sources indicate that compared to traditional wet processes, inkjet technology provides up to a 90% reduction in material consumption, up to an 80% reduction in process water consumption and up to an 80% reduction in energy consumption.

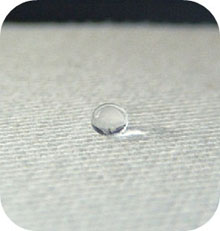

The deposition of hydrophobic coatings provides a good example for demonstrating the unique advantages of inkjet technology. Hydrophobic coatings take inspiration from the high levels of water repellence exhibited by the leaves of a lotus flower. The effect is a result of the flower’s double structured leaf surface. This double structure enables the contact area and adhesion force between surface and water droplet to drop dramatically. The leaf surface contains a typical plant epidermis but also has tiny hydrophobic wax coated papillae which span the area of the leaf. Similar to the lotus leaf, in the field of textiles hydrophobic properties can be attained by depositing a coating which reduces the surface energy of the substrate. It is easy to see why hydrophobic fabrics provide value in a wide range of applications, particularly in the field of protective clothing.

Traditional foulard and pad mangle processes imbues both sides of the substrate with the hydrophobic functionality; this can be detrimental to the handle, tactile and moisture related properties of the substrate. Hydrophobic properties on both sides of a fabric can be particularly detrimental for sports and protective clothing. In fields such as these where rigorous activity is likely to occur, it would be unhelpful for the inner side of the fabric to be liquid repellent since sweat will not be absorbed. Hydrophobic coatings on the inside of clothing can also prove to be very uncomfortable when the fabric rubs against the skin. Since the inkjet process allows single sided fluid deposition, this means the outer layer of the fabric can undergo hydrophobic coating to repel water while the inner layer can be hydrophilic to absorb sweat. Unlike foulard and pad mangle processes, there is no vat of surplus materials at the end of the process. Only as much coating is deposited as is required which means there is significantly less wastage.

The levels of water repellence offered by hydrophobic coatings help to ensure dirt particles do not settle on the fabric and are easily washed off. However, a more advanced inkjet ‘self cleaning’ coating utilising photocatalytic titanium oxide is being developed. The photocatalytic coating can chemically break down organic compounds, ensuring that dirt particles, fungal particles and microbes are destroyed. The cleansing oxidisation process is a chemical reaction created by UV light striking the titanium dioxide coating. Since titanium oxide is only the catalyst in this reaction, it never needs to be replenished and will continue to break down any pollutants which come into contact with the coating. Extensive testing has been carried out to ensure this functional coating can be jetted stably and with good coverage.

Other applications

In the field of medicine, inkjet also presents an interesting prospect as it provides single drop deposition at precise quantities. Demand for coatings in applications such as bandages for wounds where the controlled release of precise amounts of fluid is expected to increase in the future. Another potential future application for controlled release inkjet coatings is the scenting of women’s clothes, with fragrances being released in small quantities over a designated time period. Inkjet deposited flame retardant coatings (or any other functional coating for protective clothing) also benefit from being thinner and lighter than traditional coatings. This has the advantage of increased portability for the wearer which can be vital in tough environments. While the inkjet deposition of functional coatings is still in its infancy, there are unique benefits offered by the technology which manufacturers of the future would be wise to consider.

Tim Phillips, Catenary Solutions